Ukusetshenziswa kwe-aluminium extrusion ekwakhiweni komkhiqizo nasekukhiqizeni kukhule kakhulu emashumini eminyaka amuva nje.Ngokombiko wakamuva ovela kwa-Technavio, phakathi kuka-2019-2023 ukukhula kwemakethe ye-aluminium extrusion emhlabeni jikelele kuzokhula ngesivinini ngeCompound Annual Growth Rate (CAGR) ecishe ibe ngu-4%, nansi imiyalo emfushane yokuthi iyini i-aluminium extrusion, izinzuzo. inikeza, kanye nezinyathelo ezihilelekile kunqubo ye-extrusion.

Iyini i-Aluminium Extrusion?

I-Aluminium extrusion iyinqubo lapho impahla ye-aluminium ingxubevange iphoqelelwa ngefa elinephrofayili ethile ye-cross-sectional.Inqama enamandla iphusha i-aluminiyamu kwidayizi bese iphuma endaweni evulekayo.Uma iphuma, iphuma isesimweni esifanayo nesedayizi futhi ikhishwa eduze kwetafula eliphumayo.Ezingeni eliyisisekelo, inqubo ye-aluminium extrusion ilula ukuyiqonda.Amandla asetshenziswayo angafaniswa namandla owasebenzisayo lapho ukhama ishubhu lomuthi wokuxubha ngeminwe yakho.

Njengoba ukhama, umuthi wokuxubha uyavela umise ukuvuleka kweshubhu.Ukuvulwa kweshubhu lokuxubha amazinyo empeleni kusebenza umsebenzi ofanayo ne-extrusion die.Njengoba ukuvulwa kuyindilinga eqinile, i-toothpaste izophuma njenge-extrusion ende eqinile.

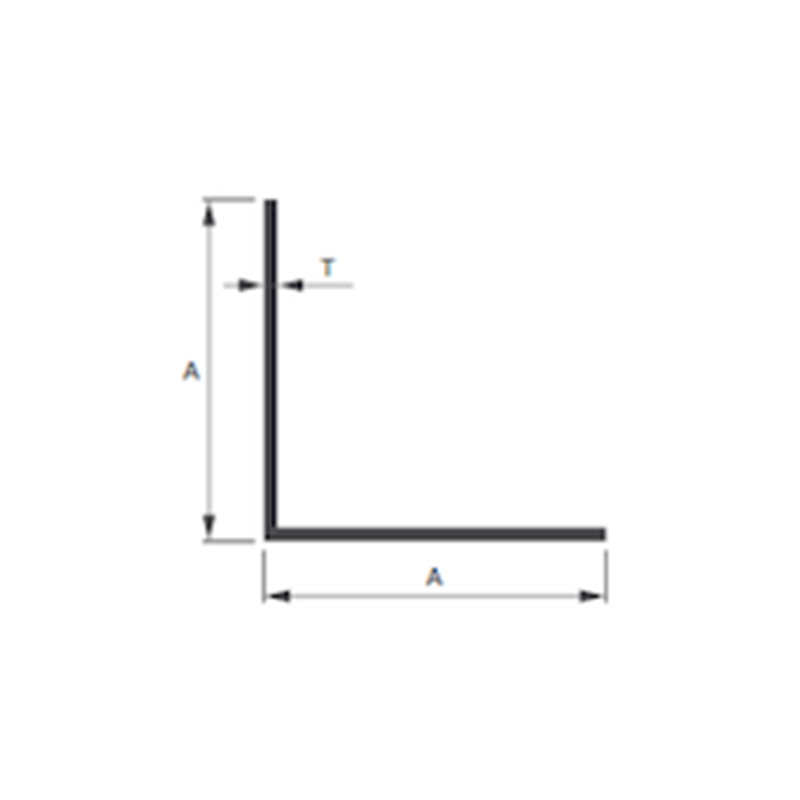

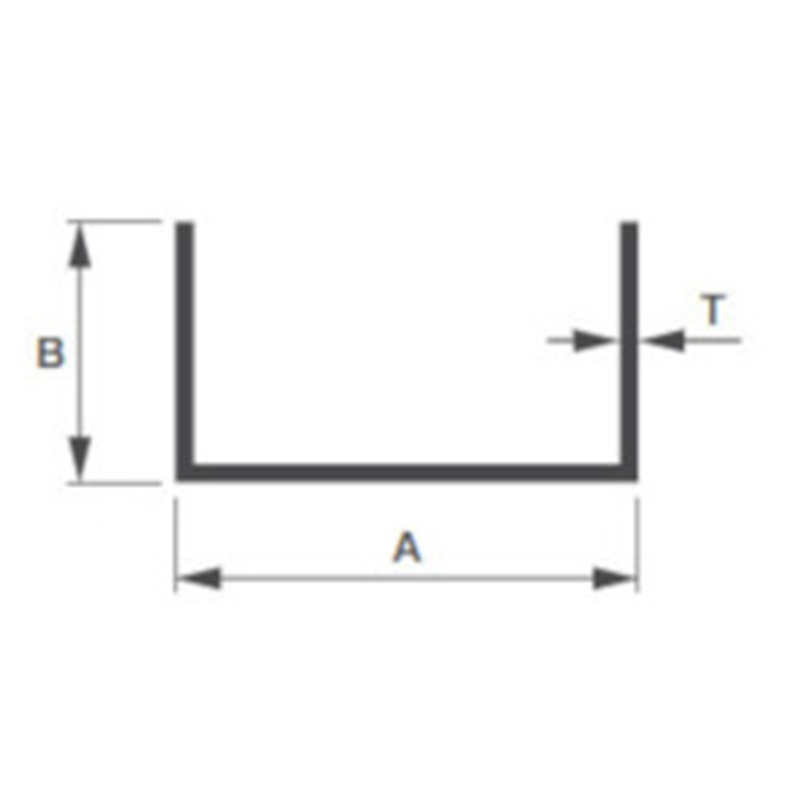

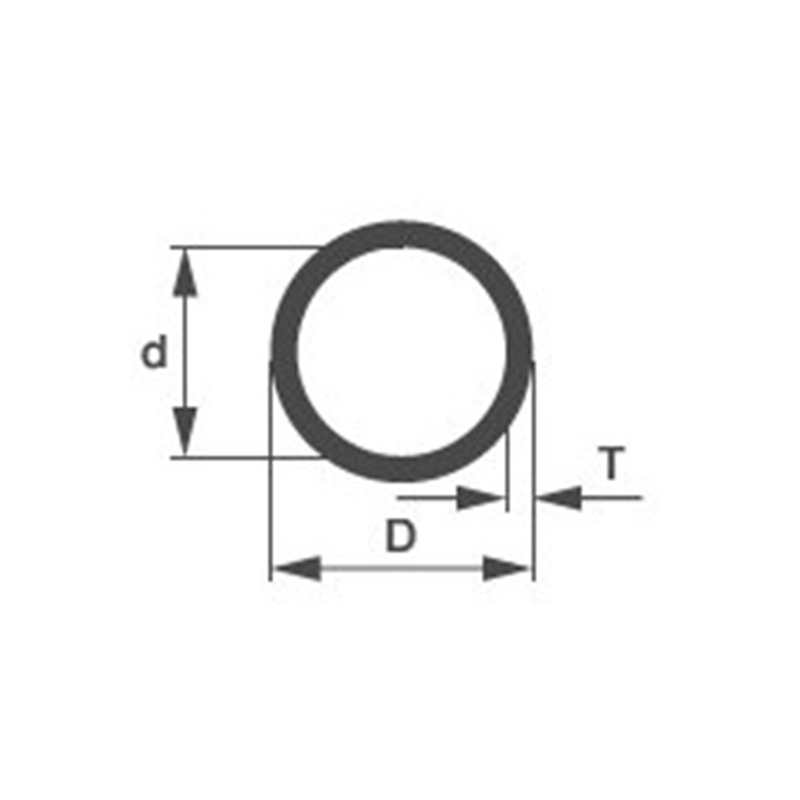

Nazi ezinye izibonelo zomumo ovame ukukhishwa: ama-engeli, amashaneli, namashubhu ayindilinga.

Kwesobunxele kukhona imidwebo esetshenziselwa ukudala ama-dies futhi kwesokudla kukhona ukuhumusha kokuthi amaphrofayili e-aluminium aqediwe azobukeka kanjani.

Umdwebo: I-Aluminium angle

Umdwebo: Isiteshi se-Aluminium

Umdwebo: I-Round Tube

Ngokuvamile, kunezigaba ezintathu eziyinhloko zomumo okhishiwe:

1. Okuqinile, engenazo izikhala ezivalekile noma izimbobo (okungukuthi, induku, ugongolo, noma i-engeli).

2. Ize, ene-void eyodwa noma ngaphezulu (okungukuthi isikwele noma ishubhu elingunxande)

3. I-semi-hollow, enezikhala ezivaleke kancane (okungukuthi, umzila “C” onesikhala esincane)

I-Extrusion inezinhlelo zokusebenza ezingenakubalwa kuzo zonke izimboni eziningi ezahlukene, okuhlanganisa ezokwakha, ezezimoto, eze-electronics, i-aerospace, amandla, nezinye izimboni.

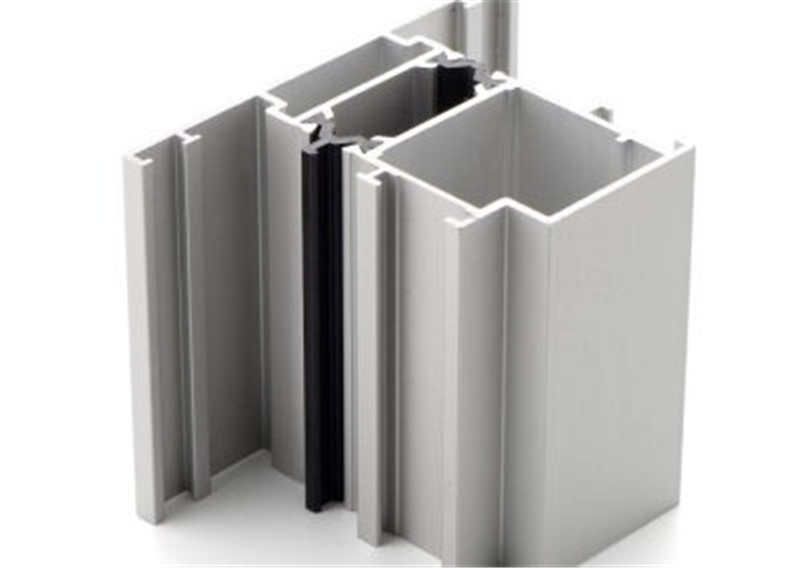

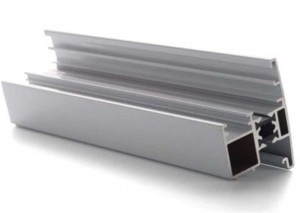

Ngezansi kukhona ezinye izibonelo zomumo oyinkimbinkimbi kakhulu owenzelwe imboni yezokwakha.

Inqubo ye-Aluminium Extrusion ngezinyathelo ezingu-10

Isinyathelo #1: I-Extrusion Die ilungisiwe futhi ihanjiswe ku-Extrusion Press

Isinyathelo #2: I-Aluminium Billet ishiswe Ngaphambili Ngaphambi Kokukhishwa

Isinyathelo #3: I-Billet idluliselwa ku-Extrusion Press

Isinyathelo #4: Inqama Iphusha I-Billet Material Esitsheni

Isinyathelo #5: Izinto Ezinwetshiwe Zivela Nge-Die

Isinyathelo #6: Ama-Extrusions Aqondiswa Ngaphakathi Kwethebula Le-Runout futhi Acinywe

Isinyathelo #7: Izandiso Zigundiwe Kubude Bethebula

Isinyathelo #8: Izandiso Zipholiswe Kuzinga lokushisa Legumbi

Isinyathelo #9: Ama-Extrusions Ayiswa Ku-Stretcher futhi Yelulelwa Ekuqondaneni

Isinyathelo #10: Izandiso Ziyiswa Kusaha Lokuqedwa futhi Sika Kubude

Uma ukukhishwa sekuqediwe, amaphrofayili angaphathwa ngokushisa ukuze kuthuthukiswe izakhiwo zawo.

Khona-ke, ngemva kokwelashwa kokushisa, bangathola ama-surface finishes ahlukahlukene ukuze bathuthukise ukubukeka kwabo nokuvikela ukugqwala.Bangakwazi futhi ukwenza imisebenzi yokwenziwa ukuze bafinyelele ezingeni labo lokugcina.

Ukwelashwa Kokushisa: Ukuthuthukisa Izakhiwo Zemishini

Ama-alloys ochungechungeni lwango-2000, 6000, kanye no-7000 angelashwa ukushisa ukuze athuthukise amandla awo okugcina aqinile futhi akhiphe ingcindezi.

Ukuze kuzuzwe lezi zithuthukisi, amaphrofayili afakwa kuhhavini lapho inqubo yawo yokuguga isheshisa futhi alethwa ekufutheni kwe-T5 noma kwe-T6.

Zishintsha kanjani izindawo zabo?Njengesibonelo, i-6061 aluminium (T4) engaphathwanga inamandla aqinile angama-241 MPa (35000 psi).I-aluminium engu-6061 (T6) efakwe ngokushisa inamandla angu-310 MPa (45000 psi).

Kubalulekile ukuthi ikhasimende liqonde izidingo zamandla zephrojekthi yabo ukuze liqinisekise ukukhetha okulungile kwe-alloy kanye nentukuthelo.

Ngemuva kokwelapha ukushisa, amaphrofayili angabuye aqedwe.

Ukuqeda Ubuso: Ukuthuthukisa Ukubukeka Nokuvikela Ukugqwala

I-Extrusions ingaqedwa futhi yenziwe ngezindlela ezihlukahlukene

Izizathu ezimbili eziyinhloko zokucabangela lezi ukuthi zingathuthukisa ukubukeka kwe-aluminium futhi zingathuthukisa izici zayo zokugqwala.Kodwa kunezinye izinzuzo futhi.

Isibonelo, inqubo ye-anodization ijiya isendlalelo se-oxide sensimbi esenzeka ngokwemvelo, sithuthukise ukumelana nokugqwala futhi senze insimbi imelane nokuguga, ithuthukise ukukhishwa kwamanzi, futhi inikeze indawo enembobo engamukela odayi abanemibala ehlukene.

Ezinye izinqubo zokuqeda ezifana nokudweba, ukugcotshwa kwempushana, ukuqhunyiswa kwesihlabathi, kanye ne-sublimation (ukwakha ukubukeka kokhuni), nakho kungenziwa.

Ngaphezu kwalokho, kunezinketho eziningi zokwenza ama-extrusions.

Ukwenziwa: Ukufinyelela Izilinganiso Zokugcina

Izinketho zokwenziwa zikuvumela ukuthi ufinyelele ubukhulu bokugcina obufunayo kuma-extrusions akho.

Amaphrofayli angashaywa, abhobhodwe, afakwe ngomshini, asikwe, njll. ukuze ahambisane nemininingwane yakho.

Isibonelo, ama-fin kumaheatsink e-aluminium extruded angenziwa ngomshini ukuze kwakheke idizayini yephini, noma izimbobo zezikulufu zingabhodlwa zibe ucezu lwesakhiwo.

Ngaphandle kwezidingo zakho, kunenhlobonhlobo yokusebenza engenziwa kumaphrofayili e-aluminium ukuze kwakheke afanele iphrojekthi yakho.

I-Aluminium Extrusion Iwuhlelo Lokukhiqiza Olubalulekile Uma udinga ukufunda kabanzi mayelana nendlela yokuthuthukisa ingxenye yakho yedizayini yenqubo yokukhishwa, pls zizwe ukhululekile ukuxhumana namaqembu e-YSY okuthengisa nawonjiniyela, sikulungele noma nini lapho udinga.

Isikhathi sokuthumela: Jul-05-2022